CHALLENGE:

Anglo American is a leading global mining company and requested the design, manufacturing, commissioning and start-up services for an AMPO POYAM pumping station protection valve in its Pumping station in Santo Antonio do Grama (MG, Brazil).

SOLUTION:

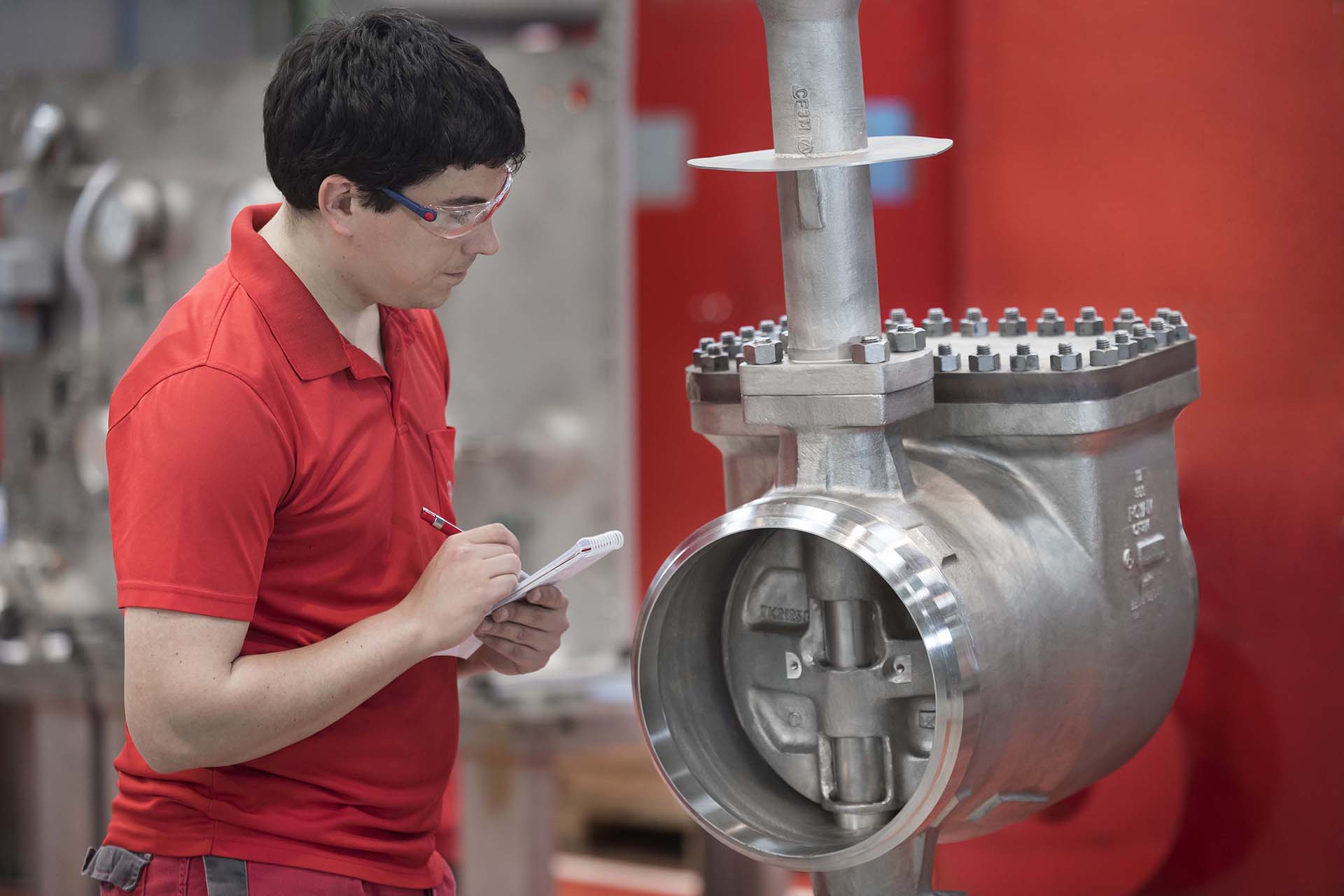

A Severe Service Slurry Ball Valve was designed, manufactured and installed at the pumping station 2 of the ferro duct that conveys the iron from the mine to the port for further transport. The purpose of this valve is to protect the pump of the station. When a pump is shut down, the valve closes the conduit to prevent the fluid from returning and damaging the pump. These types of valves are key in the protection of the pumps, as well as in making the maintenance in the safest way possible.

AMPO POYAM VALVES supplied this highly engineered and severe service slurry ball valve on a test basis in 2018 with a commitment to put it into operation in May 2019. The AMPO SERVICE team carried out the supervision of the installation of the valve in the field and also its validation and supervision after a 6-month operating period. Since then, ANGLO AMERICAN has had the opportunity to test firsthand the performance of the valve. Thanks to the optimal performance of the valve, AMPO POYAM VALVES was technically validated as a supplier for severe service ball valves.

Since then, AMPO POYAM VALVES has successfully supplied 23 severe service slurry ball valves more (up to 10” and 1500 lbs) for two new pumps in the existing pumping station in Santo Antonio do Grama (MG) and for a new pump in the existing pumping station in Conceição do Mato Dentro (MG), both in Brazil. AMPO SERVICE has also provided on-site after sales services, supporting the construction, commissioning and start-up processes.

This is a severe service in which the process data must be analyzed very carefully since an incorrect selection of design, construction materials or the overlay can lead to the valve becoming inoperable in a very short time. It must be taken into account that the slurry being conveyed through the valve could contain solid particles of considerable size (the iron). Thus, the valve must have a high erosion resistance and must be robustly designed to ensure the operation and tightness of the line for a considerable amount of time.

To this end, our Research and Development team is able to perform simulations of the fluid with the process data obtained. The simulations define the optimal design, materials, and overlays for the best performance of the valve.

It has been thanks to the work of the R&D and the AMPO SERVICE teams, and the teams that have supported them during this project, that our specially designed severe service valves are the best option for this type of application.