LNG & Gas processing and transportation

Natural-gas processing is a complex industrial process designed to clean raw natural gas by separating impurities and various non-methane hydrocarbons and fluids to produce what is known as natural gas.

LNG

AMPO can support customers in the main LNG (Liquefied Natural Gas) processes such as:

- LNG liquefaction, storage and export facilities

- LNG/LPG/Oil tankers (LNGC/LPGC) transportation

- LNG receiving terminals, storage and regasification / FSRUs

- FPSO

- Floating LNG (FLNG)

- Peak shaving terminals

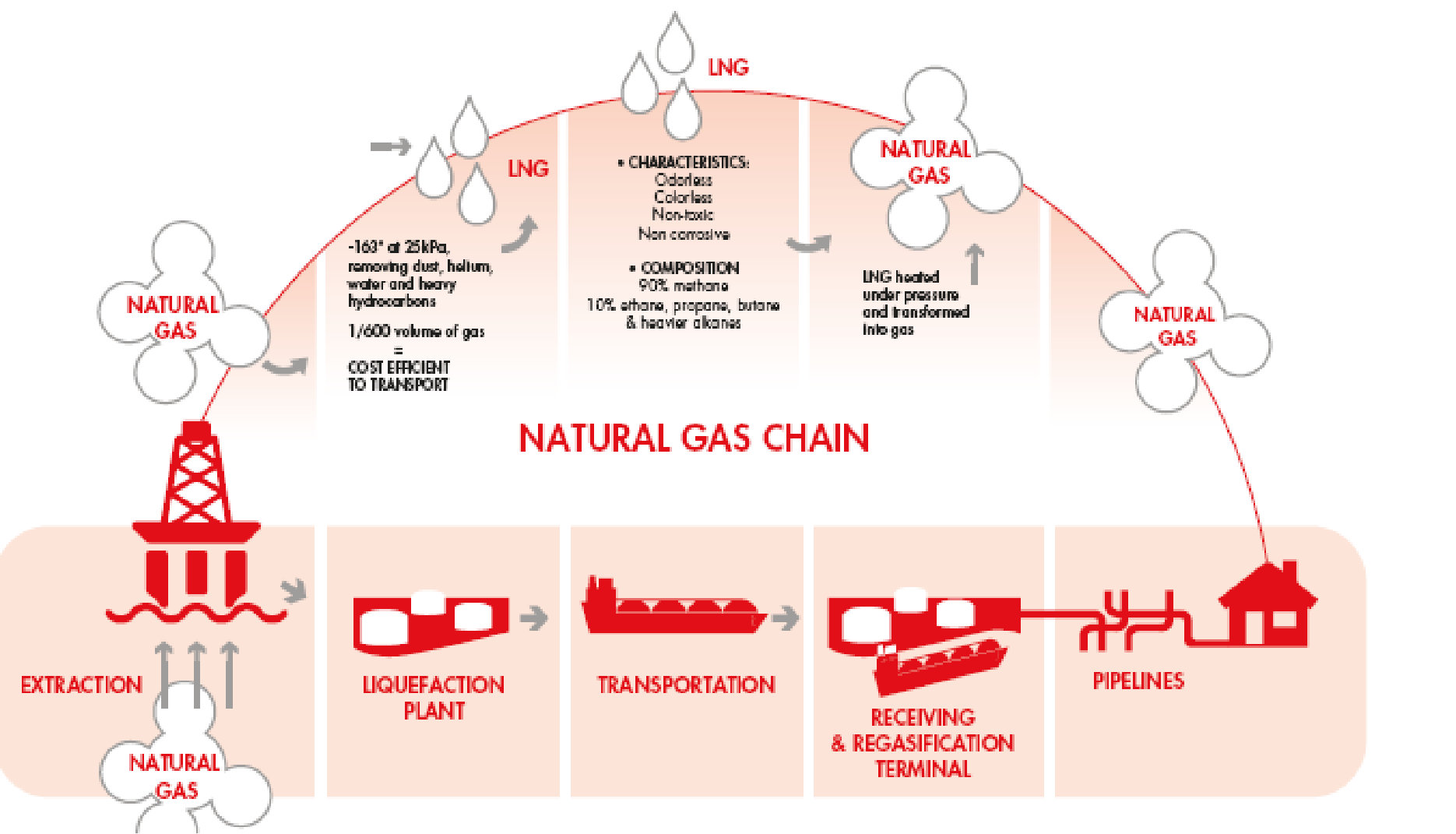

Here you can find the schemes for the main LNG chain processes:

LNG Liquefaction LNG Receiving Terminal

See our valves for LNGGas processing and transportation

With natural gas’s unique position as a source of clean energy and a feedstock for several chemical products, it’s become increasingly important to monetize these resources efficiently and effectively. AMPO has extensive experience and knowledge offering solutions, products, and technologies for LNG (liquefied natural gas), GTL (gas-to-liquid), and ammonia facilities, which can optimize production and increase the value of these resources.

Our team has a wide experience in the field of engineering, operation, and troubleshooting of gas compression, conditioning, and processing facilities, including amine acid gas treating units, cryogenic and non-cryogenic NGL extraction, fractionation plants, and associated unit operations such as gas dehydration, butane isomerization, and sulfur recovery.

View our valves for Gas Processing and TransportationGas-to-Liquids (GTL)

Gas to liquid (GTL) involves processes to convert natural gas into liquid products such as transport fuels, plastics, cosmetics,…

AMPO supports customers in GTL Processes.

Hydrogen

Hydrogen is the most abundant element in the universe. Even though it’s light and small, hydrogen is a powerful energy carrier – one kg of hydrogen carries three times the energy of kerosene. It can be used to store excess renewable energy and then transported underground through an extensive network of pipelines or overland by truck to be applied to a wide range of applications, from mobility to heavy industries. Due to its versatility, hydrogen is proving to be a key enabler of the transition to low and zero-carbon energy – clean energy, to help meet climate change targets.

AMPO is fully engaged with the different technologies to develop the best solution in each and every case.

See our green hydrogen storage solutions

See our valves for Hydrogen

Hydrogen

Hydrogen can be stored either as a gas or as a liquid. Hydrogen gas storage typically requires the use of high-pressure tanks (350-700 bar or 5000-10,000 psi), while liquid hydrogen storage requires cryogenic temperatures to prevent it boiling back into a gas (which occurs at −252.8°C). Hydrogen can also be stored on the surface of (adsorption) or within solid materials (absorption).

Main storage options:

Compressed:

Compressed hydrogen is a storage form in which hydrogen gas is kept under pressure to increase the storage density.

Liquified:

Liquified hydrogen is a storage form in which the liquified hydrogen is kept liquid and requires cryogenic temperatures, as the boiling point of hydrogen at one atmosphere pressure is −252.8°C.

Ammonia:

Ammonia is considered to be a potential medium for hydrogen storage, facilitating CO2-free energy systems in the future. Its high volumetric hydrogen density, low storage pressure and stability for long-term storage are among the beneficial characteristics of ammonia for hydrogen storage.

Hydrogen can be transported either by:

Pipeline:

Hydrogen pipeline transport is used to transport hydrogen from the point of production or delivery to the point of demand. Hydrogen pipeline transport is technologically mature and the transport costs are similar to those of CNG.

Liquified in tanks:

Hydrogen is most commonly transported and delivered as a liquid when high-volume transport is needed in the absence of pipelines.

Ammonia:

Ammonia is the favored mechanism to transport hydrogen over large distances. Firstly, the cost of energy storage is cheaper than for either hydrogen or liquified petroleum gas. Secondly, ammonia contains more hydrogen by volume than either pipelines or liquid hydrogen.

Carbon Capture

Carbon Capture and Storage (CCS) is a way of reducing carbon emissions, which could be key to helping to tackle global warming. It’s a three-step process, involving: capturing the carbon dioxide produced by power generation or industrial activity, such as steel or cement making; transporting it; and then storing it deep underground.

See our valves for Carbon CaptureBiofuels

Biofuels play an important role in energy transition needs as we move to sustainable solutions in concert with the international community. Due to changing public policies, increased government incentives and growing consumer demand, biofuels have become an advanced solution for low-carbon energy, drawing the attention of oil and gas companies, the agro-industry, chemical companies and wood processing industries.

See our valves for BiofuelsSynthetic fuels

Synthetic fuel or synfuel is a liquid fuel, or sometimes gaseous fuel, obtained from syngas, a mixture of carbon monoxide and hydrogen, in which the syngas was derived from gasification of solid feedstocks such as coal or biomass or by reforming of natural gas.

See our valves for Synthetic fuels