Capabilities

Engineering and R&D

Innovative solutions

At AMPO POYAM VALVES we are committed to innovation, with a highly qualified multidisciplinary team in place, fully dedicated to the development of new products, technologies and systems. Their lifelong training ensures that we remain at the forefront of our industry.

At AMPO we also spend more than 2% of our turnover on innovation in continued pursuit of the answers to the challenges of today and tomorrow.

In collaboration with our customers’ engineering teams and international research centers with experts in specific fields, we continuously aim to develop high technological value solutions in response to our customers’ needs.

Video

AMPO’s main innovation and research areas correspond to the following operational strands:

At AMPO we are involved in the pursuit and development of new solutions, allowing society to progress towards the energy transition required for decarbonization. This has prompted us continuously to add new technological solutions to our valves so as to achieve “zero emissions” valves, as well as developing new valves for energy transition in the fields of hydrogen, carbon capture, biofuels and synthetic fuels.

We are members of the European Hydrogen Alliance and BH2C (the Basque Hydrogen Corridor), as well as being co-founders of the Energy Intelligence Center, a flagship institution based at a technology park and focused on Industry 4.0 and advanced manufacturing.

Safety is non-negotiable for us, which is why we keep ourselves busy devising improvements and new solutions in this sphere.

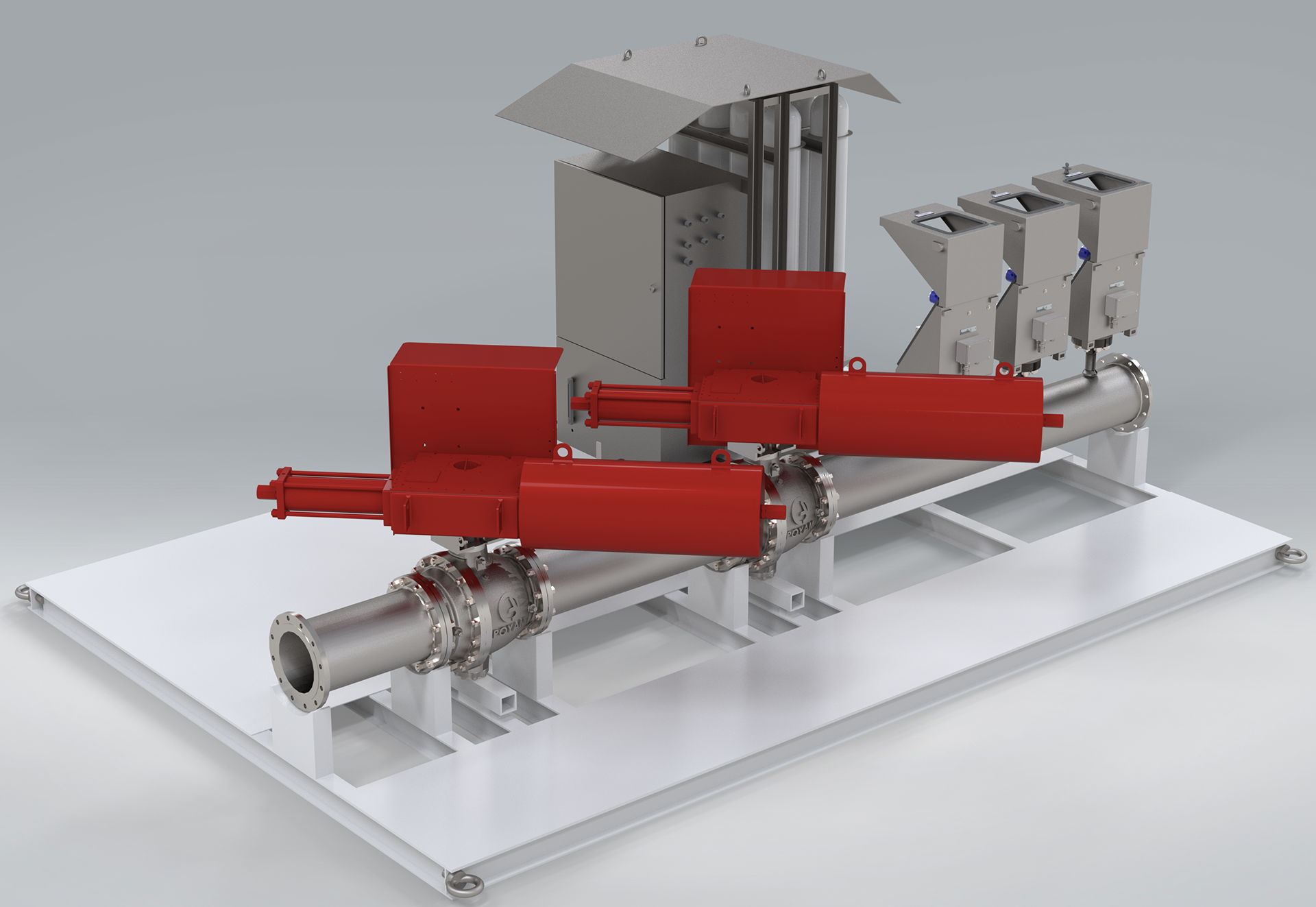

Our remote control processes, our ISS (Integrated Smart Solutions), new preventive maintenance equipment and new control systems are just some of the solutions we offer. All of which furthermore hold the most demanding certifications in terms of safety, such as Exida certification and the SIL standards.

AMPO POYAM VALVES places the utmost importance on the reliability of its products and systems, together with processes for the development and performance of new projects.

Discover our ISS solutions

AMPO is a leader in the development, design and manufacture of valves for the most severe services. Industrial processes are increasingly complex and demanding, forcing us to remain at the forefront of our industry, delivering high technological value solutions for the most extreme applications. To do so we adapt our designs so as to improve the service life of our valve components; develop technological solutions and surface treatments to minimize premature wear and friction between different components; select materials and overlays on an ad hoc basis for each project, along with integration elements suited to the application conditions, etc.

At AMPO POYAM VALVES we know that only the very best product can avoid the corrosion, abrasion, adhesion or erosion caused by severe service, and so increase its service life. And so analyses of fluid capacities, tribological overlays and process studies are just some of the tasks performed by the AMPO POYAM VALVES engineering team.

Valve evaluation and Test Labs

AMPO has numerous test benches in place to evaluate the designs of its solutions and developments under the most DEMANDING operating conditions, so as to guarantee OPTIMAL VALVE FUNCTIONALITY for each service.

Valve evaluation and Test Labs

HIGH TEMPERATURE testing

HIGH PRESSURE testing

ENDURANCE testing

VACUUM testing

CRYOGENIC testing

Helium testing

Valve evaluation and Test Labs

It also has access to equipment and laboratories to characterize specific overlays and materials used in its valves, so as to offer the most appropriate solutions for each service.

Valve evaluation and Test Labs

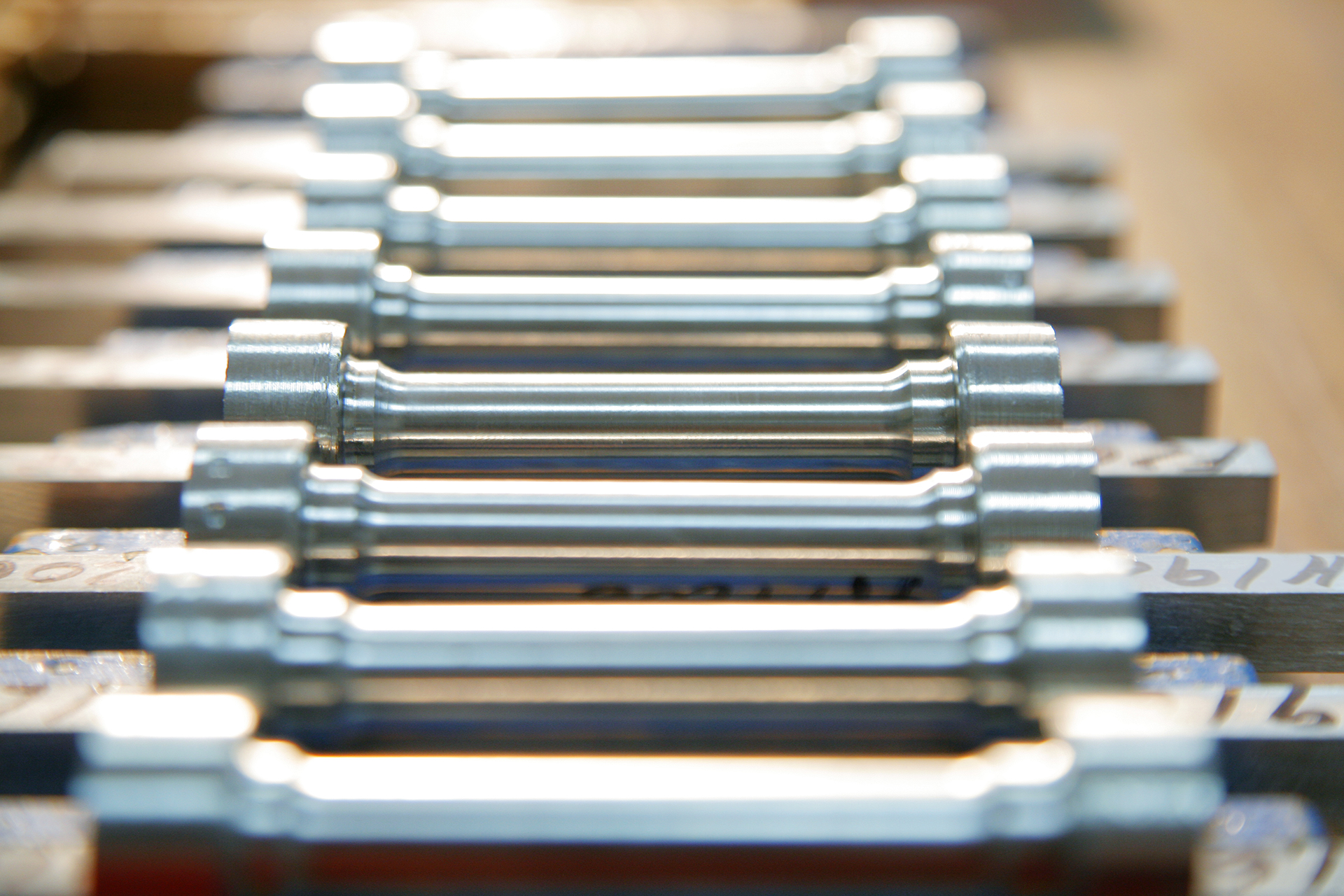

HARDWEARING MATERIAL TESTS

(1) Internally designed test bench, developed to characterize overlays in conditions with high concentrations of suspended solids. This characterization uses CFD to simulate the influence of each type of overlay in terms of the lifespan of internal valve components; (2) abrasion characterization equipment; (3) equipment to analyze the type of failure suffered by an overlay.

MECHANICAL CHARACTERIZATION OF MATERIALS

(1) Equipment for materials characterization under different temperature conditions (-150 ºC to 800 ºC), (2) mechanical fatigue, (3) creep etc.

CHARACTERIZATION OF MATERIALS IN RESPONSE TO CORROSION

(1) Laboratories and autoclaves to evaluate materials under different corrosive service conditions

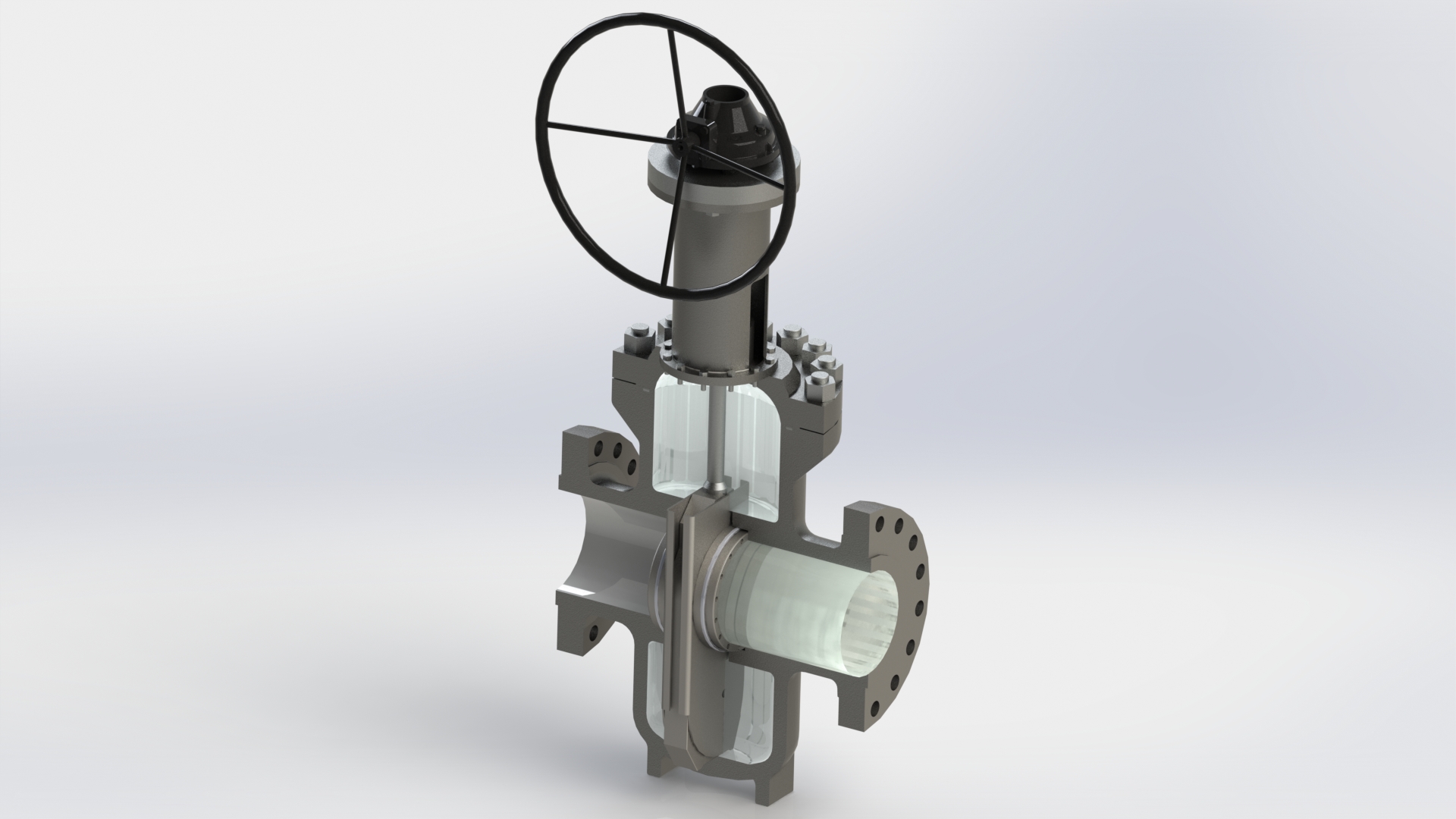

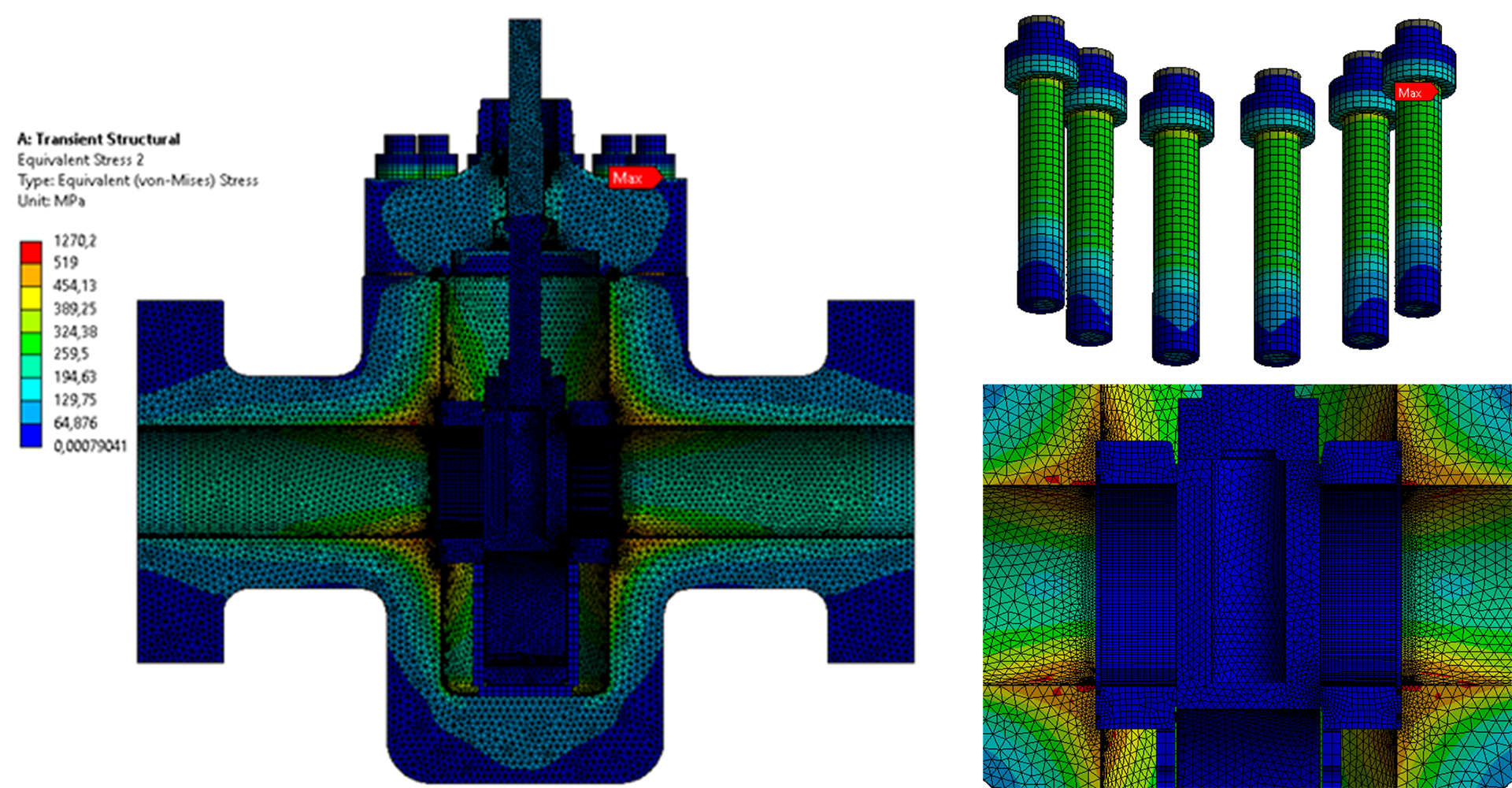

Virtual Design Validation

AMPO has the very latest 3D design and simulation software to validate and optimize the design and functionality of its valves, combined with extensive experience and capacity in evaluating the most relevant operational conditions for its valves:

- Mechanical and structural simulations

- Thermal simulations

- Fluid dynamics simulations

- Multi-physical simulations to evaluate the interaction of different domains

- Correlation of operating torques

- P&ID analysis

- Cv calculations

- Seismic calculations

Root Cause Analysis

Our multidisciplinary engineering and R&D team’s services allow our clients to deal with the specific problems or challenges faced by their equipment and processes, evaluating possible failure modes and offering alternative solutions.

Discover our Tailored engineering solutions