Capabilities

Quality

Committed to Quality

Our goal is to provide our customers with the highest levels of quality and reliability, while furthermore leading the technological development of the fluid handling industry.

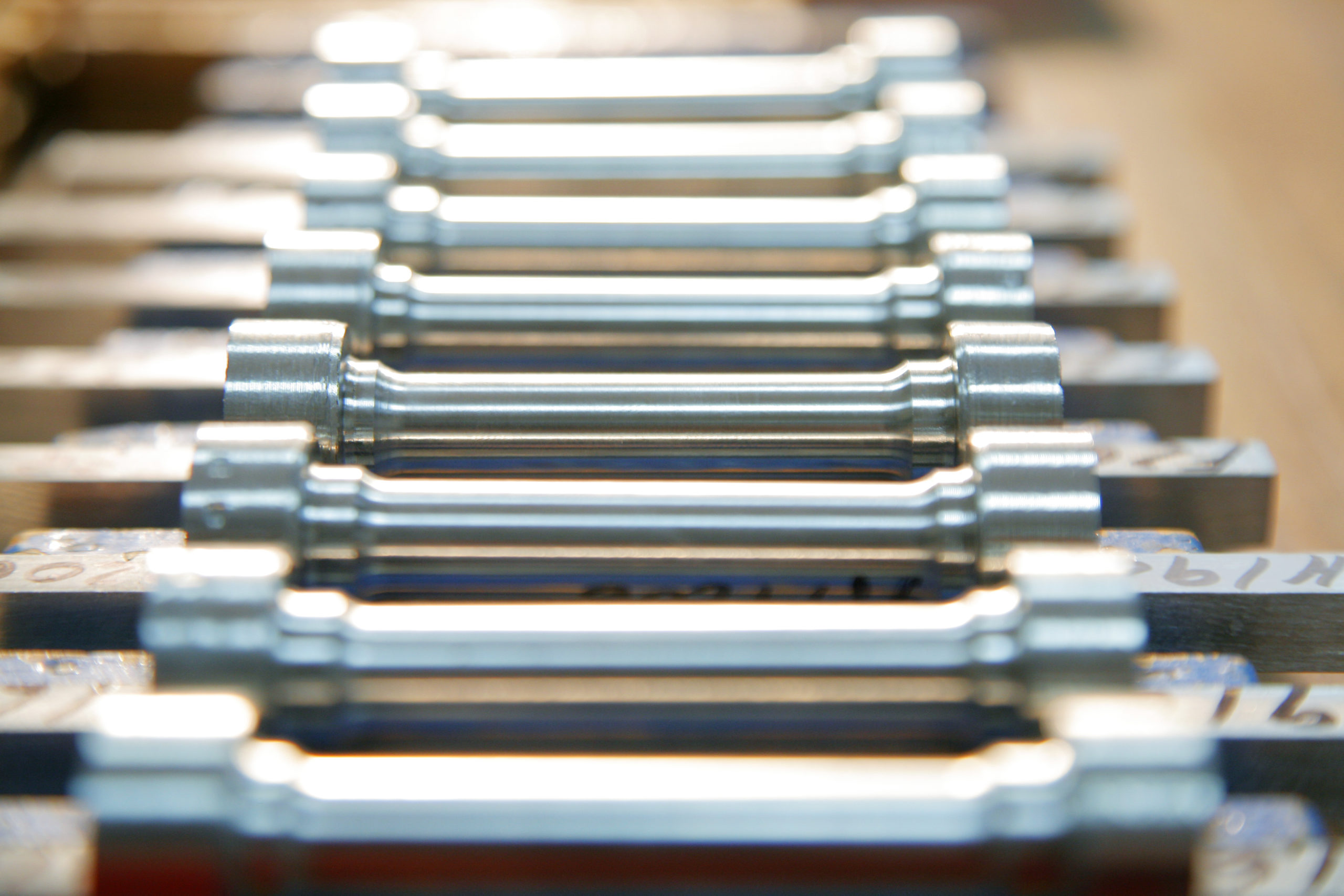

At AMPO we guarantee optimal quality, and so perform intermediate and final inspections in all our production areas. These inspections are documented with the corresponding reports and certifications, are coordinated directly by an efficient and highly qualified team, and conducted always in accordance with both internal and external quality assurance standards and procedures. Every step, from purchase order receipt through procurement, non-destructive testing (NDT), machining, weld overlays, assembly, testing, painting and packaging, are performed in accordance with the regulations stipulated in the Quality Assurance Manuals.

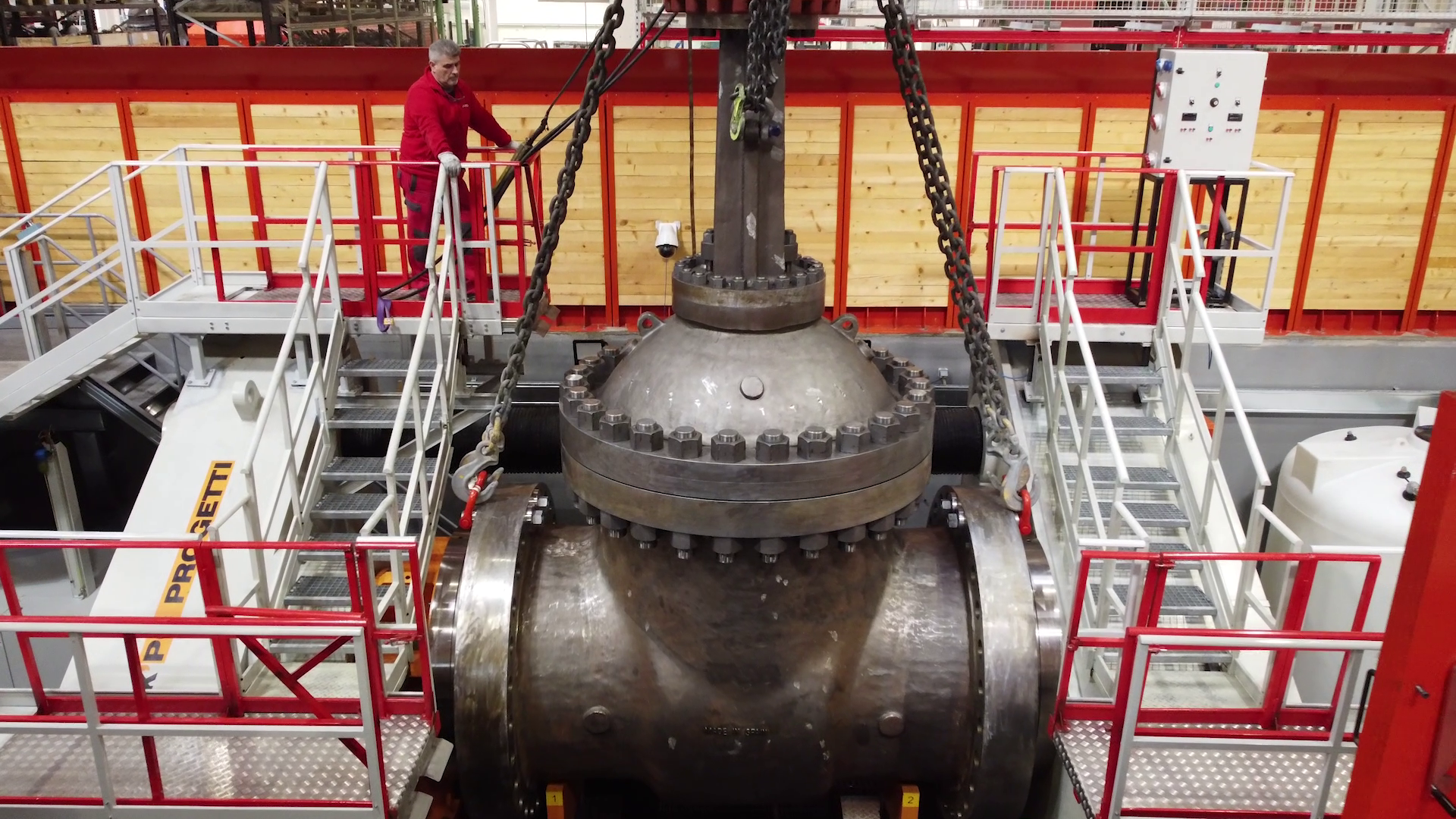

We also check all our valves before delivery, and offer our customers the chance to be present on site for these tests. We have working areas at AMPO where inspectors can work at their convenience.

Quality tests and laboratories

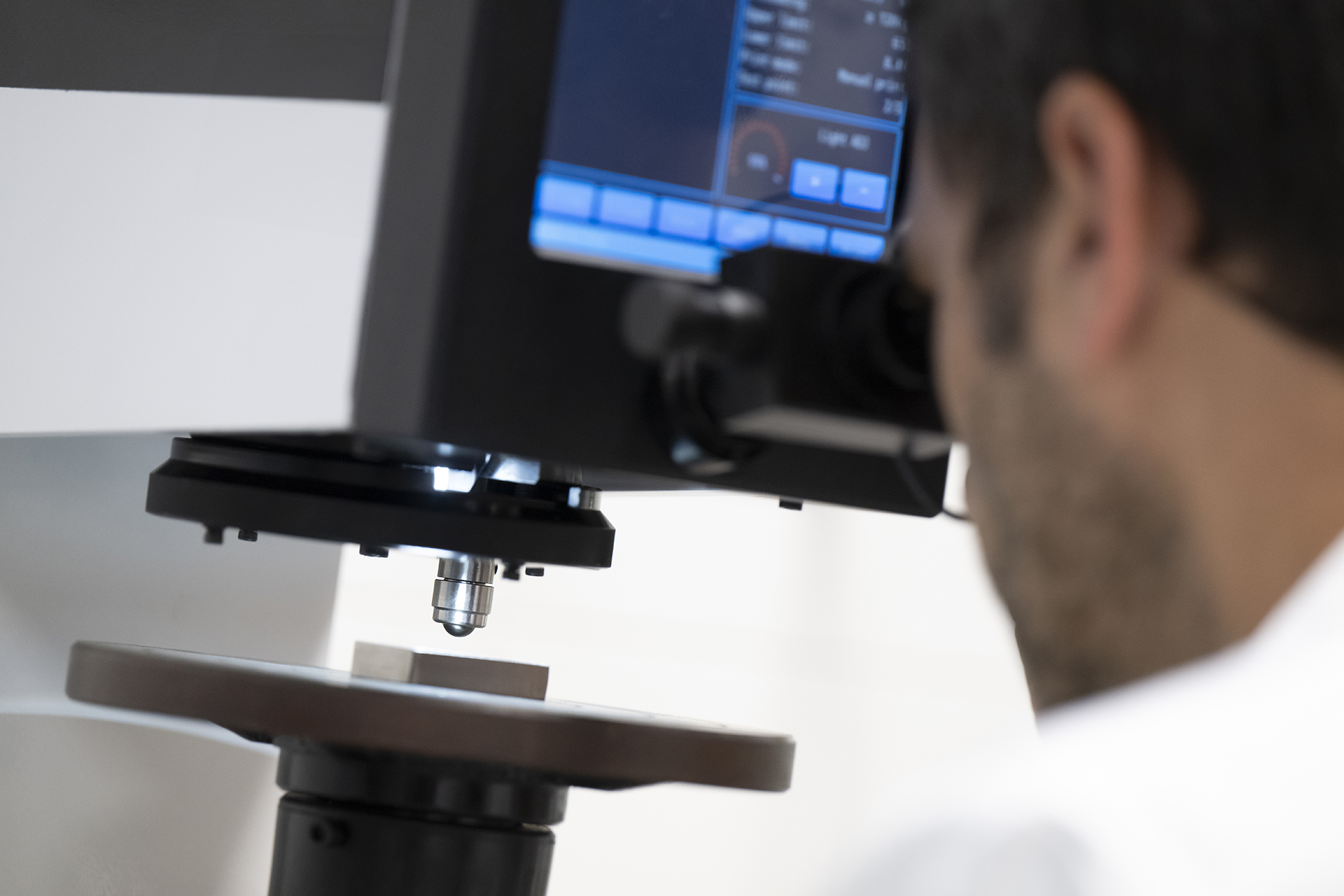

We likewise have the very latest testing facilities and highly qualified Internal Quality Control personnel to guarantee the reliability of our solutions. We conduct:

Quality tests and laboratories

Non-Destructive Tests, such as: X-rays, dye penetrants tests, ultrasonic tests, magnetic particle tests, PMI (Positive Materials Identification), visual inspections, hydrostatic tests, pneumatic tests, cryogenic or low-temperature tests, fugitive emissions tests, vacuum tests, high-temperature tests, high-pressure tests, PR2F tests to check the integrity of the valves and their components, etc.

Laboratory tests: Chemical tests, mechanical tests, impact tests, hardness measurements, ferrite content tests, metallography analyses and corrosion tests.

Quality tests and laboratories

Our management processes are fully based on the strictest quality standards, as the bedrock allowing AMPO to develop the product best suited to customer needs. All our solutions comply with FAT (Factory Acceptance Tests), but at AMPO we always go the extra mile in terms of the quality and reliability we demand. We therefore continuously conduct extreme tests based on the service conditions of our solutions.

Quality System

Our production processes are implemented and overseen by applying a quality assurance system. These processes have since 1991 been approved under standards ISO 9001, API spec Q1 & 6D, SIL 3 and NORSOK and accredited by the leading external organizations on the market, such as Lloyd’s Register, Bureau Veritas (BV), Det Norske Veritas (DNV) and American Bureau (ABS). All our solutions furthermore carry CE and UKCA marking.